Hemp Paper

Hemp is a truly remarkable plant.

It is easy to grow, requires minimal care, and produces a large crop every 16 weeks subject to favourable weather conditions.

Hemp has been utilized for over 10,000 years for many applications, the history of hemp is breathtaking when you realize the historical importance of this now demonized crop.

Fast forward to today and hemp is rapidly regaining its status as a plant prized for its many uses. It’s estimated that every month over 1 million people use hemp CBD oil which is primarily produced from industrial hemp.

Cannabis users are also becoming interested in hemp for its low THC high CBD buds and flowers which are rapidly becoming a popular legal substitute for marijuana.

Hemp is a plant that keeps on giving, so even when the seeds and hemp oil has been extracted, the biomass can also be used for a variety of applications.

Hemp paper is one such use that is currently experiencing a renewal of interest.

Producing pulp and paper from trees casts an ecological shadow far beyond its impact on the world’s forests. Converting trees into paper uses large amounts of water, energy, and chemicals and generates vast amounts of air and water pollution.

The pulp and paper industry is the fifth largest consumer of energy, accounting for 4% of all the world’s energy use.

The pulp and paper industry uses more water to produce a ton of product than any other industry.

Consumers play a pivotal role in reshaping the future of the pulp and paper industry.

40% of office paper still ends up in overburdened landfills.

Expanding the reuse of paper reduces the pressure to cut more trees, reduces demand on overburdened waste disposal systems and cuts energy use and pollution. One ton of recycled paper produces one ton of new paper, which is far more efficient than using virgin wood fiber.

Annual plants such as flax and hemp have been used in papermaking for thousands of years.

Non-wood fibers such as flax and hemp are rapidly renewable resources that can contribute to more environmentally-sound fiber blends.

Flax and hemp yield longer fibers and can assist in creating a high quality paper when added to shorter fiber resources such as recycled office paper (post-consumer waste).

1 ton of Living Tree Paper Company’s Vanguard Recycled Plus* requires 43.69% less energy to produce the same amount of virgin pulp paper. That is an energy-saving equal to 4,920 Kilowatt Hours of Electricity, an amount equivalent to operating the average Northwest home for 6 months. This reduces the atmospheric emissions of Greenhouse Gases by 2097 pounds, an amount equal to driving the average car for 2468 miles.

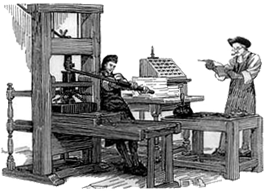

Hemp fabric was smashed down into thin sheets to make the world’s first paper. 75-90% of all paper in the world was made with hemp fiber until 1883. The Gutenberg Bible, Thomas Paine’s pamphlets, and the novels of Mark Twain were all printed on hemp paper. In the UK, the Magna Carta was printed on hemp paper. Both the U.S. Constitution and the Declaration of Independence were drafted on hemp and then copied onto parchment.

Both the long bast fiber and the short bast fiber (hurd or pulp) can be used to make paper. Fiber paper is thin, tough, brittle, and rough. Pulp paper is not as strong but is easier to make, softer, thicker, and preferable for most everyday purposes.

In the next 20-30 years the paper demand is expected to at least double due to the economic emergence of third world countries, and the ever-expanding worldwide population. There is no way to meet this demand without clear-cutting every tree in the entire world. Paper is big business, and 93% of the world’s paper is made of wood. Think about how much of a difference it would make if commercial industries like London hotels, San Francisco hotels and Miami hotels were to adopt hemp toilet paper. That alone could make an enormous difference in the way the war on global warming is fought.

Making paper from trees is kind of a joke because trees are made up of only 30% cellulose. The other 70% of the tree must be removed using toxic chemicals until the cellulose can be formed into paper. The higher the percentage of cellulose in a plant, the better, because fewer chemicals need to be used, and less work needs to be done before the paper can be made. Almost any plant in nature with a strong stalk is better suited to make paper than trees, especially hemp because it can be 85% cellulose.

If our planet had the choice of us using hemp paper versus tree paper, the choice would be hemp. There are zero sound reasons to destroy wildlife and habitats when there is an environmentally friendly option.

Hemp makes the paper stronger and which lasts centuries longer than wood paper, which could be very valuable for people who want to keep records aside from on computers. Hemp paper does not yellow, crack, or otherwise deteriorate as tree paper does now. The acids which are needed for wood paper eventually eat away at the pulp and cause it to turn yellow and fall apart. Because of this publishers, libraries, and archives have to order specially processed acid-free paper, but they could just buy hemp paper which already meets their quality standards.

Hemp paper also does not require any bleaching, and so does not poison the water with dioxins or chlorine-like tree paper mills do. The chemicals involved in making hemp paper are much less toxic, in fact, both paper made from hemp hurd, and from the long bast fiber can be made without any chemicals at all, but it takes longer to separate the fiber from the lignin. Making paper from hemp could also eliminate erosion due to logging, reduces topsoil loss, and water pollution caused by soil runoff.

One acre of hemp can produce as much paper as 4 to 10 acres of trees over a 20-year cycle, but hemp stalks only take four months to mature, whereas trees take 20 to 80 years. This information was known in 1916, according to a USDA report. Hemp paper can also be recycled more often, though this fact is not of much value since hemp is a reusable resource.

Since 1937, when hemp was effectively outlawed, 70% of American natural forests have been destroyed. Today, only 4% of Americaís old-growth forest remains standing, and there is talk of building roads into that for logging purposes! Hemp growing could completely negate the necessity to use wood at all because anything made from wood can be made from hemp.

The plant kenaf is better suited than hemp for making some qualities of paper, but hemp has one huge advantage, hemp generates an immense amount of plant matter in a four-month growing season. Plants like Kenaf just cannot produce enough plant material to make enough paper for what the world demand is and will soon become, making hemp the only organic paper which makes sense. If hemp farming were only geared toward papermaking, it would still be a giant move to improve the planet.

Germany’s largest paper company converted two mills to hemp-based paper production, even though large mills require 40-60% of the equipment to be retooled to switch to hemp-based paper. Hemp paper is the one area of the possible hemp market that would require a lot of equipment change, but the need exists to change the equipment, or we will not be left with any more trees for shade, scenery, and good old-fashioned air. The construction costs to convert our paper mills from tree-based paper to hemp is around $100-300 million, which would at the same time open doors for new jobs and opportunities to build new equipment.

The reason for these equipment changes lies in the fact that the hemp fiber is so strong. The chains of cellulose molecules are arranged as a rigid structure glued together by the lignin, which must be separated before the fiber can be made into paper.

Hemp currently makes up around .05% of the world annual pulp production volume at around 120,000 tons/year because importation costs result in prices which are 2-3 times that of tree paper, but Living Tree Paper Company out of Oregon is starting to make headway. Their paper, which is 10% hemp flax & 90% post-consumer waste, is now being sold in 1,000 Staples stores across the country. Next time you need paper for your computer, choose the paper which is friendly to the environment. One of Living Tree Paper Company’s slogans is, “The paper you choose says as much about you as the image you print on it.

“Leaf of God 2 “; professional-quality inkjet print on art paper, handmade by Hemphasis staff, of hemp fiber.

Hemp Leaf print on Pine Ridge Hemp Paper

The image is that of a hemp leaf, harvested, pressed and scanned in 2007. It has been printed on heavy handmade hemp art paper, cut out and mounted on another sheet of handmade hemp art paper.

The sheet is 81/2″ x 11″. It is handmade by Hemphasis staff of about 85% Pine Ridge hemp fiber, about 12% recycled hemp paper, about 2% various native plants from Pine Ridge, and some blue hemp fiber recycled from a pair of hemp trousers. This sheet is a little thicker than standard construction paper.

“PictoBison 1”; professional-quality inkjet print on cardstock, handmade by Hemphasis staff, of hemp fiber, mounted on hemp art paper.

The image is an actual pictograph created by prehistoric people. Its dimensions are about 51/2″ x 37/8″. It is printed on 100% Pine Ridge hemp fiber handmade cardstock. That print has been mounted on an extra-thick piece of about 90% hemp paper, made of a combination of Pine Ridge hemp, recycled hemp paper, native grasses, and pulverized pine bark, all from Pine Ridge.

The effect is somewhat like a piece of hide with a picture on it glued to another, rougher piece of hide. Overall dimensions are about 10″ x 71/2″.

“Leaf of God “; professional-quality inkjet print on art paper, handmade by Hemphasis staff, of hemp fiber.

“Leaf of God “; professional-quality inkjet print on art paper, handmade by Hemphasis staff, of hemp fiber.

Hemp Leaf print on hemp paper

The image is that of a hemp leaf, harvested, pressed and scanned in 2007. The sheet is about 101/2″ x 15″. It is handmade by Hemphasis staff of about 85% Pine Ridge hemp fiber, about 12% recycled hemp paper, and about 3% various native plants from Pine Ridge.

This sheet is about the weight and thickness of construction paper.

You will swear that it is an actual leaf lying on the paper, but it’s not; it’s an inkjet print of a hemp leaf.

“PictoBison 2 “; professional-quality inkjet print on art paper, handmade by Hemphasis staff, of hemp fiber.

The image is an actual pictograph created by prehistoric people. It is printed on 98% hemp fiber handmade art paper made of a combination of Pine Ridge hemp, recycled hemp paper, recycled hemp trouser fibers and cattail fluff all from Pine Ridge.

The effect is somewhat like a piece of hide with a picture on it. Overall dimensions are about 10″ x 8 “